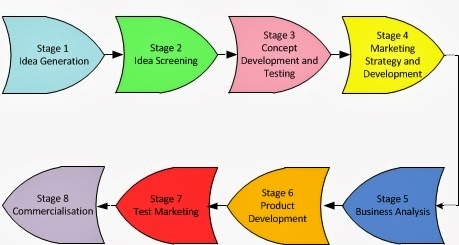

Stages of the New Product Development (NPD) Process

New-Product Development Process:

New product development is a process which is designed to develop, test and consider the viability of products which are new to the market in order to ensure the Growth or survival of the organization.

Every entrepreneur knows that productivity is one of the key ingredients for successful product development. New product development (NPD) is the complete process of bringing a new product to market. A product is a set of benefits offered for exchange and can be tangible (that is, something physical you can touch) or intangible (like a service, experience, or belief).

Stages of New Product Development:

New product development as the first stage in generating and commercializing new product within the overall strategic process of product life cycle management used to maintain or grow their market share.

1. Idea Generation

Every entrepreneur knows that productivity is one of the key ingredients for successful product development. New product development (NPD) is the complete process of bringing a new product to market. A product is a set of benefits offered for exchange and can be tangible (that is, something physical you can touch) or intangible (like a service, experience, or belief).

Stages of New Product Development:

New product development as the first stage in generating and commercializing new product within the overall strategic process of product life cycle management used to maintain or grow their market share.

- Idea Generation

- Idea Screening

- Concept Development and Testing

- Business Analysis

- Market Testing

- Technical Implementation

- Commercialization

- New Product Pricing

Stages of the New Product Development Process

1. Idea Generation

- Idea Generation is often called the "NPD" of the NPD process. Idea generation is continuous, systematic search for new product opportunities. It involves delineating sources of new ideas and methods for generating them.

- Ideas for new products can be obtained from basic research using a SWOT analysis (Strengths, Weaknesses, Opportunities & Threats). Market and consumer trends, company's R&D department, competitors, focus groups, employees, salespeople, corporate spies, trade shows, or ethnographic discovery methods (searching for user patterns and habits) may also be used to get an insight into new product lines or product features.

- Lots of ideas are generated about the new product. Out of these ideas many are implemented. The ideas are generated in many forms. Many reasons are responsible for generation of an idea.

- Idea Generation or Brainstorming of new product, service, or store concepts - idea generation techniques can begin when you have done your OPPORTUNITY ANALYSIS to support your ideas in the Idea Screening Phase (shown in the next development step).

2. Idea Screening

The object is to eliminate unsound concepts prior to devoting resources to them.

The object is to eliminate unsound concepts prior to devoting resources to them.

- The screeners should ask several questions:

- Will the customer in the target market benefit from the product?

- What is the size and growth forecasts of the market segment / target market?

- What is the current or expected competitive pressure for the product idea?

- What are the industry sales and market trends the product idea is based on?

- Is it technically feasible to manufacture the product?

- Will the product be profitable when manufactured and delivered to the customer at the target price?

3. Concept Development and Testing

Concept testing present the consumer with a proposed product and measure attitudes and intention at this early stage of development.

Concept testing present the consumer with a proposed product and measure attitudes and intention at this early stage of development.

- Develop the marketing and engineering details

- Investigate intellectual property issues and search patent databases

- Who is the target market and who is the decision maker in the purchasing process?

- What product features must the product incorporate?

- What benefits will the product provide?

- How will consumers react to the product?

- How will the product be produced most cost effectively?

- Prove feasibility through virtual computer aided rendering and rapid prototyping

- What will it cost to produce it?

- Testing the Concept by asking a number of prospective customers what they think of the idea - usually via Choice Modelling.

4. Business Analysis

Includes development of three part strategy plan

Includes development of three part strategy plan

- Describe the market’s size, structure, and behaviour, the planned product positioning, and the sales, market share, and profit goals for first few years.

- Outlines the planned price, distribution strategy, and marketing budget for the first year.

- Describes thelong-run sales and profit goals and marketing-mix strategy over time.

- Test marketing involves placing a product for sale in one or more selected areas and observing its actual performance under the proposed marketing plan

- Produce a physical prototype or mock-up

- Test the product (and its packaging) in typical usage situations

- Conduct focus group customer interviews or introduce at trade show

- Make adjustments where necessary

- Produce an initial run of the product and sell it in a test market area to determine customer acceptance

6. Technical Implementation

- New program initiation

- Finalize Quality management system

- Resource estimation

- Requirement publication

- Publish technical communications such as data sheets

- Engineering operations planning

- Department scheduling

- Supplier collaboration

- Logistics plan

- Resource plan publication

- Program review and monitoring

- Contingencies - what-if planning

7. Commercialization

- Launch the product

- Produce and place advertisements and other promotions

- Fill the distribution pipeline with product

- Critical path analysis is most useful at this stage

8. New Product Pricing

- Impact of new product on the entire product portfolio

- Value Analysis (internal & external)

- Competition and alternative competitive technologies

- Differing value segments (price, value and need)

- Product Costs (fixed & variable)

- Forecast of unit volumes, revenue, and profit

Comments

Post a Comment