Techniques of Work Measurement and Their Applications

Work measurement (WM)

Work measurement is the application of techniques designed to establish the time for a qualified worker to carry out specified jobs at a defined level of performance.

Work measurement (WM) is concerned with investigating, reducing and eliminating ineffective time, whatever may be the cause.

WM is the means of measuring the time taken in the performance of an operation or series of operations in such a way that the ineffective time is shown up and can be separated out.

Work measurement is also called by the name ‘time study’. Work measurement is absolutely essential for both the planning and control of operations. Without measurement data, we cannot determine the capacity of facilities or it is not possible to quote delivery dates or costs. We are not in a position to determine the rate of production and also labor utilization and efficiency.

It may not be possible to introduce incentive schemes and standard costs for budget control.

Objectives of Work Measurement

The use of work measurement as a basis for incentives is only a small part of its total application.

The objectives of work measurement are to provide a sound basis for:

For the purpose of work measurement, work can be regarded as:

1. Repetitive work: The type of work in which the main operation or group of operations repeat continuously during the time spent at the job. These apply to work cycles of extremely short duration.

2. Non-repetitive work: It includes some type of maintenance and construction work, where the work cycle itself is hardly ever repeated identically.

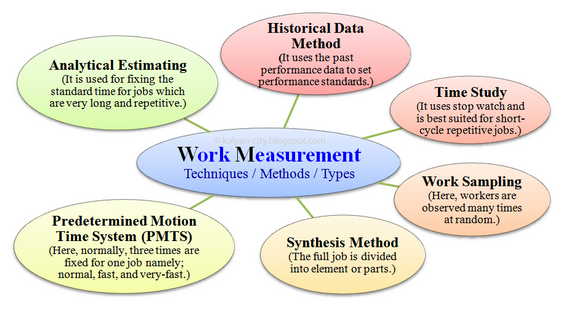

Various techniques of work measurement are:

1. Time study: A work measurement technique for recording the times and rates of working for the elements of a specified job carried out under specified conditions and for analysing the data so as to determine the time necessary for carrying out the job at the defined level of performance. In other words measuring the time through stop watch is called time study.

2. Synthetic data: A work measurement technique for building up the time for a job or pans of the job at a defined level of performance by totalling element times obtained previously from time studies on other jobs containing the elements concerned or from synthetic data.

3. Work sampling: A technique in which a large number of observations are made over a period of time of one or group of machines, processes or workers. Each observation records what is happening at that instant and the percentage of observations recorded for a particular activity, or delay, is a measure of the percentage of time during which that activities delay occurs.

4. Predetermined motion time study (PMTS): A work measurement technique whereby times established for basic human motions (classified according to the nature of the motion and conditions under which it is made) are used to build up the time for a job at the defined level of performance. The most commonly used PMTS is known as Methods Time Measurement (MTM).

5. Analytical estimating: A work measurement technique, being a development of estimating, whereby the time required to carry out elements of a job at a defined level of performance is estimated partly from knowledge and practical experience of the elements concerned and partly from synthetic data.

The work measurement techniques and their applications are shown in Table.

Table: Work measurement techniques and their application

Work measurement (WM) is concerned with investigating, reducing and eliminating ineffective time, whatever may be the cause.

WM is the means of measuring the time taken in the performance of an operation or series of operations in such a way that the ineffective time is shown up and can be separated out.

Work measurement is also called by the name ‘time study’. Work measurement is absolutely essential for both the planning and control of operations. Without measurement data, we cannot determine the capacity of facilities or it is not possible to quote delivery dates or costs. We are not in a position to determine the rate of production and also labor utilization and efficiency.

It may not be possible to introduce incentive schemes and standard costs for budget control.

Objectives of Work Measurement

The use of work measurement as a basis for incentives is only a small part of its total application.

The objectives of work measurement are to provide a sound basis for:

- Comparing alternative methods.

- Assessing the correct initial manning (manpower requirement planning).

- Planning and control.

- Realistic costing.

- Financial incentive schemes.

- Delivery date of goods.

- Cost reduction and cost control.

- Identifying substandard workers.

- Training new employees.

For the purpose of work measurement, work can be regarded as:

1. Repetitive work: The type of work in which the main operation or group of operations repeat continuously during the time spent at the job. These apply to work cycles of extremely short duration.

2. Non-repetitive work: It includes some type of maintenance and construction work, where the work cycle itself is hardly ever repeated identically.

|

| Techniques of Work Measurement |

- Time study (stop watch technique),

- Synthesis,

- Work sampling,

- Predetermined motion and time study,

- Analytical estimating.

1. Time study: A work measurement technique for recording the times and rates of working for the elements of a specified job carried out under specified conditions and for analysing the data so as to determine the time necessary for carrying out the job at the defined level of performance. In other words measuring the time through stop watch is called time study.

2. Synthetic data: A work measurement technique for building up the time for a job or pans of the job at a defined level of performance by totalling element times obtained previously from time studies on other jobs containing the elements concerned or from synthetic data.

3. Work sampling: A technique in which a large number of observations are made over a period of time of one or group of machines, processes or workers. Each observation records what is happening at that instant and the percentage of observations recorded for a particular activity, or delay, is a measure of the percentage of time during which that activities delay occurs.

4. Predetermined motion time study (PMTS): A work measurement technique whereby times established for basic human motions (classified according to the nature of the motion and conditions under which it is made) are used to build up the time for a job at the defined level of performance. The most commonly used PMTS is known as Methods Time Measurement (MTM).

5. Analytical estimating: A work measurement technique, being a development of estimating, whereby the time required to carry out elements of a job at a defined level of performance is estimated partly from knowledge and practical experience of the elements concerned and partly from synthetic data.

The work measurement techniques and their applications are shown in Table.

Table: Work measurement techniques and their application

Techniques

|

Applications

|

Unit of measurement

|

1. Time study

|

Short cycle repetitive jobs.

Widely used for direct work.

|

Centiminute (0.01 min)

|

2. Synthetic Data

|

Short cycle repetitive jobs.

|

Centi minutes

|

3. Working sampling

|

Long cycle jobs/heterogeneous operations.

|

Minutes

|

4. MTM

|

Manual operations confined to

one work centre.

|

TMU (1 TMU = 0.006 min)

|

5. Analytical estimation

|

Short cycle non-repetitive job.

|

Minutes

|

Comments

Post a Comment